EasyClean™ Compact Loaf Mold-Rectangular

- No need for a slab splitter. Save money and time.

- No need for liners. Simply brush melted solid oils (whatever you are using for the new batch) on the panels. It is effortless to unmold in 10-12 hours after the pour and the surface of the loaves are extremely smooth.

- Perfect square loaves every time.

- Dent-free loaves. You can remove loaves as long as they have formed the shape, even when they are still a little warm or soft, and you don’t need to worry about denting the loaves, like with silicone molds.

- Contamination free. It WILL NOT retain the scent, therefore it will never contaminate the next batch, which is the biggest disadvantage of silicone molds.

- Convertible. You can convert it to a slab mold for cool swirl designs.

- Stackable. You can set up the mold in a container with a lid and stack them up to save space.

- Versatile loaf sizes and loaf amount.

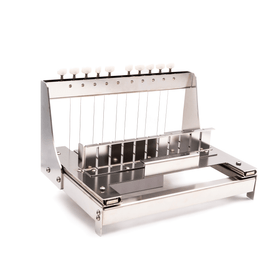

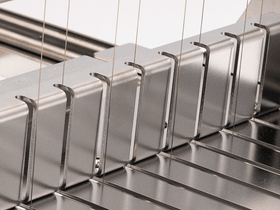

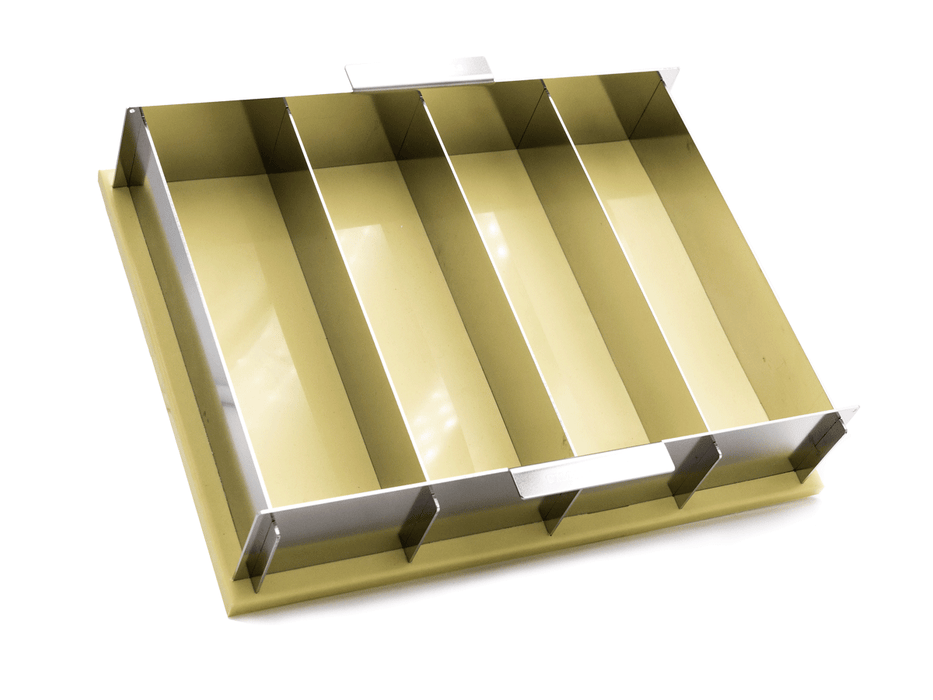

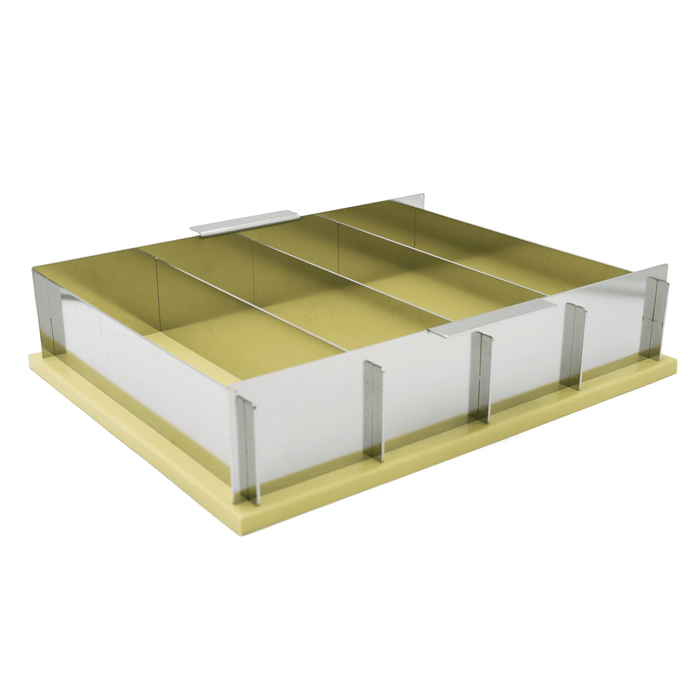

Our EasyClean™ Compact Loaf Mold-Rectangular, an interlocked soap mold, consists of seven pieces of 14 gauge heavy-duty stainless steel panels, one silicon pad, and sixteen pieces of linings.

All stainless steel panels and silicone pad perfectly interlock with each other to provide the most steady and square chambers for soap solution with tight seal.

Thanks to the poreless nature of stainless steel, our mold won’t retain any scents after it has been washed.

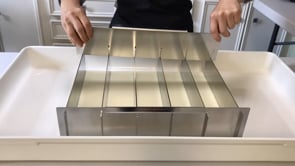

Our EasyClean™ Compact Loaf Mold-Rectangular comes with a silicone pad with grooves that hold the interlocked structure in place and make installation super easy. When it is time to remove the soaps from the mold, simply pull out the panels from the pad.

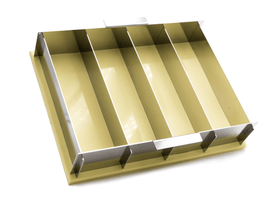

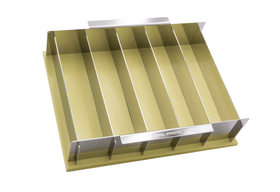

You can take it apart for easy storage when you are finished with your project. It produces 44 bars of 1"x 2.5" x 3.5" soaps per use, total approximately 14 Lbs.

The whole structure is compact, precise, easy to use, and make five perfectly square soap loaves.

It makes 1~4 loaves each time depending on how many chambers are filled up. It can be easily converted to a slab mold by only installing four outer panels and covering the gaps on the panels with polyester liners (included).

SPECS

Materials: 14 gauge stainless steel, silicone base and 5mil clear polyester linings.

Finish: Electropolishing shiny finish

Dimension: 3-1/2" H x 12-1/4" W x 15-5/8" L

(8.8 cm x 31.4 cm x 39.7 cm)

Weight: 105 oz (4.0 kg)