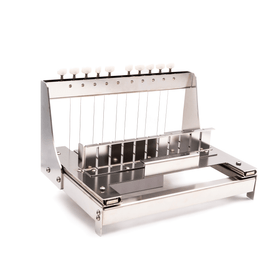

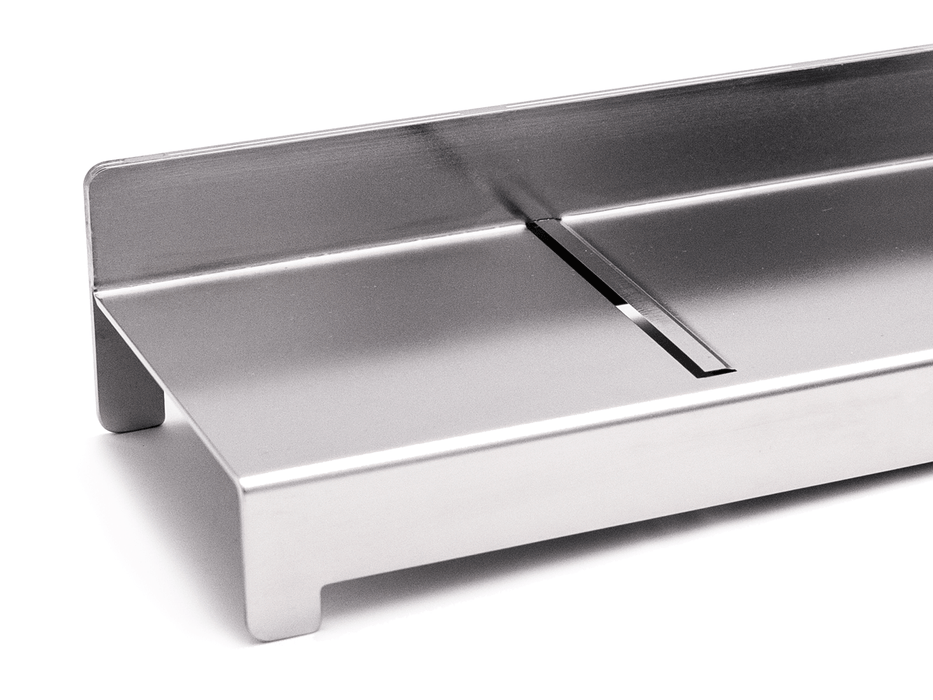

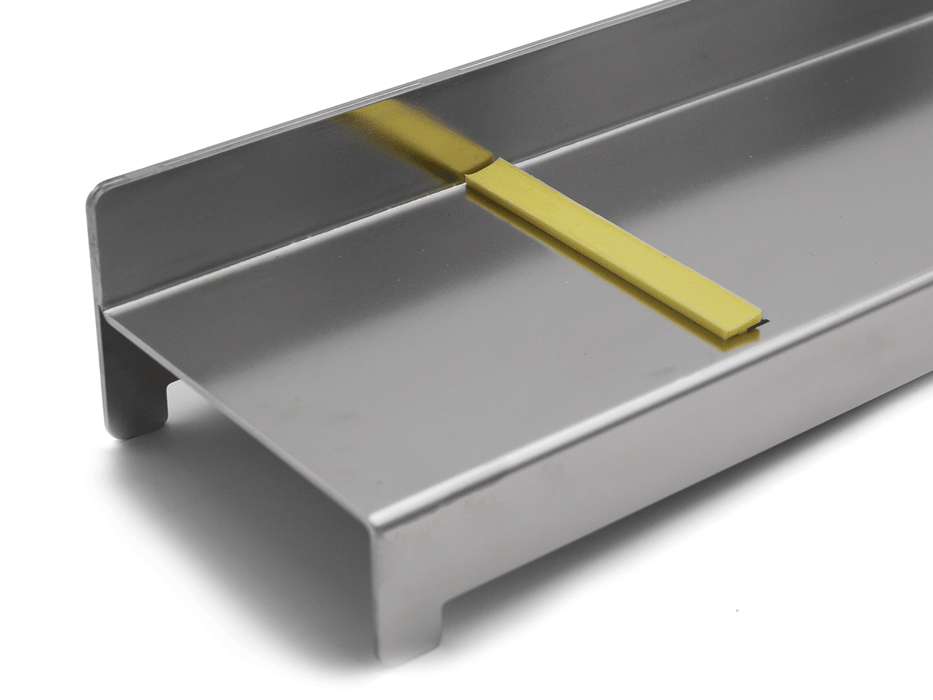

SmoothTrim™ Soap Planer

- Trouble-free bladeless design.

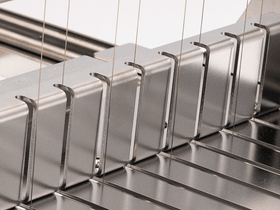

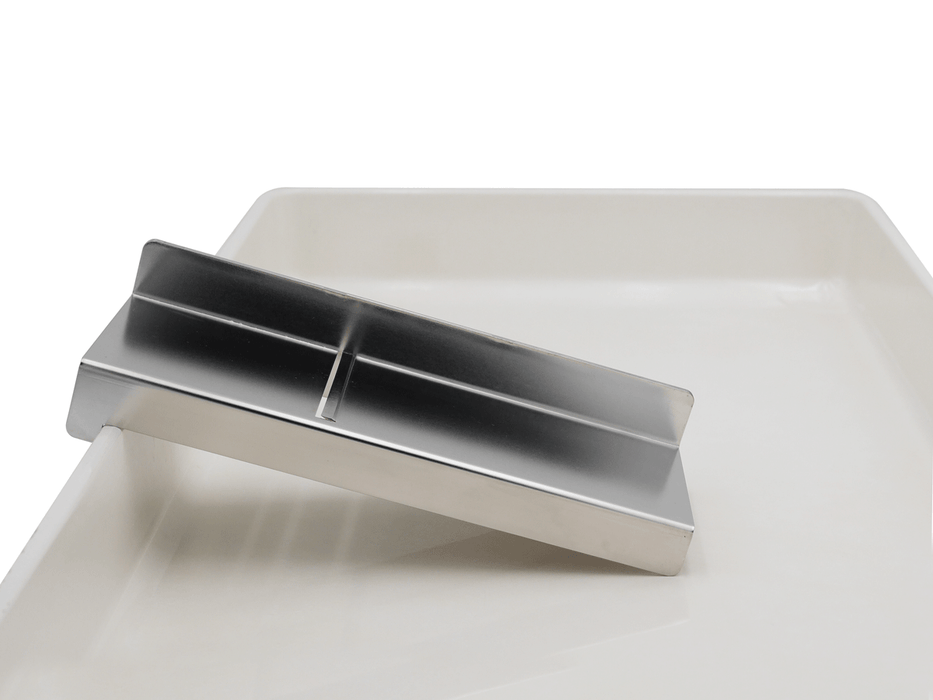

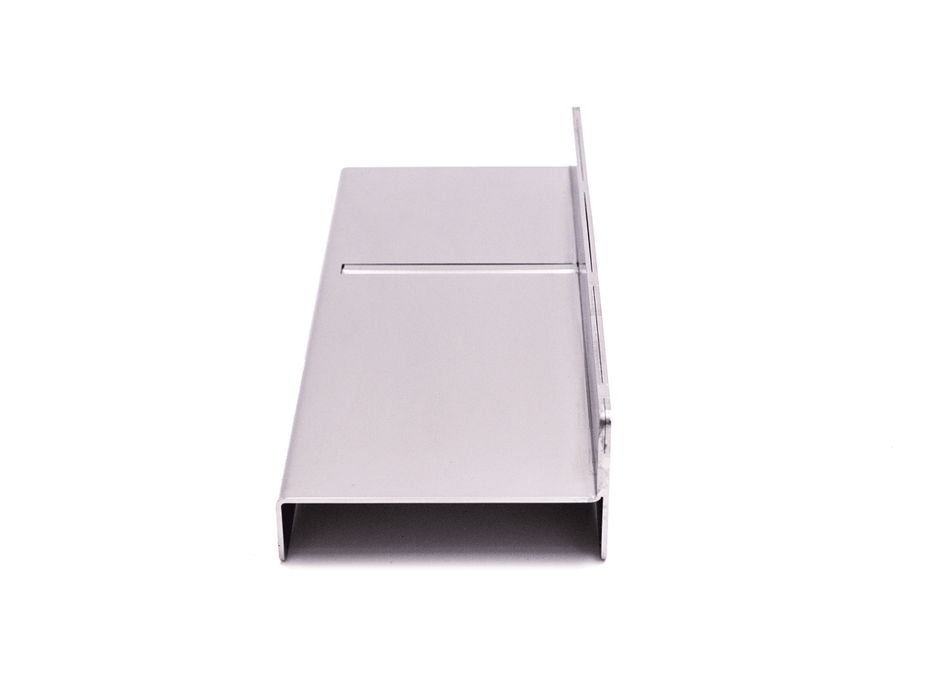

- "Hook" structure makes it easy to grip on the edge of your workbench and effortlessly trim your soap.

- Easily removes soda ash surfaces.

- It is a cinch to clean in a sink or dishwasher.

- Perfect tool for making swirls or samples.

- Use it as a sculpting tool to create 3-D looks.

With the "hook" feature, our SmoothTrim™ Soap Planer allows you to place this device over the outside edge of your workbench or container, and trim your soap with very little effort.

Our soap trimmer is much more durable and easy to maintain than the blade-loaded wood or acrylic soap planers on the market.

This versatile tool allows you to trim your soap to a perfect square and bevel the edge all in one movement, or you can also trim and bevel the edges of your soap separately.

It is a one-piece tool without a blade, therefore you don’t have to worry about replacing blades forever. It is easy to use and a cinch to clean!

Please note that this planer does NOT come with a beveling feature. It is particularly designed for those soapers who ONLY want to smooth out the rough or uneven surface without beveling edges.

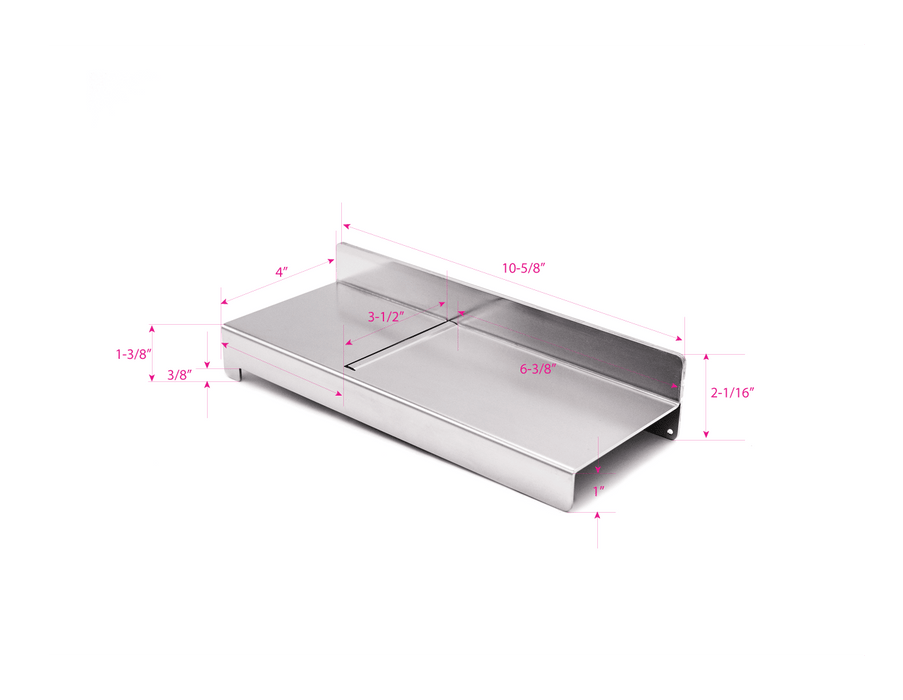

SPECS

Materials: 14 gauge 304 stainless steel and silicone safety strip.Finish: Glossy nickel finish.

Dimension: 2-1/2" H x 4" W x 10-5/8" L (6.2 cm x 10.2 cm x 27.0 cm)

"Lip" height: 9/16" (1.5 cm)

Trimming Thickness: average 0.35-0.4 mm depending on the pressure you apply on the soap against the trimming edge.

Weight: 30 oz (0.85 kg)