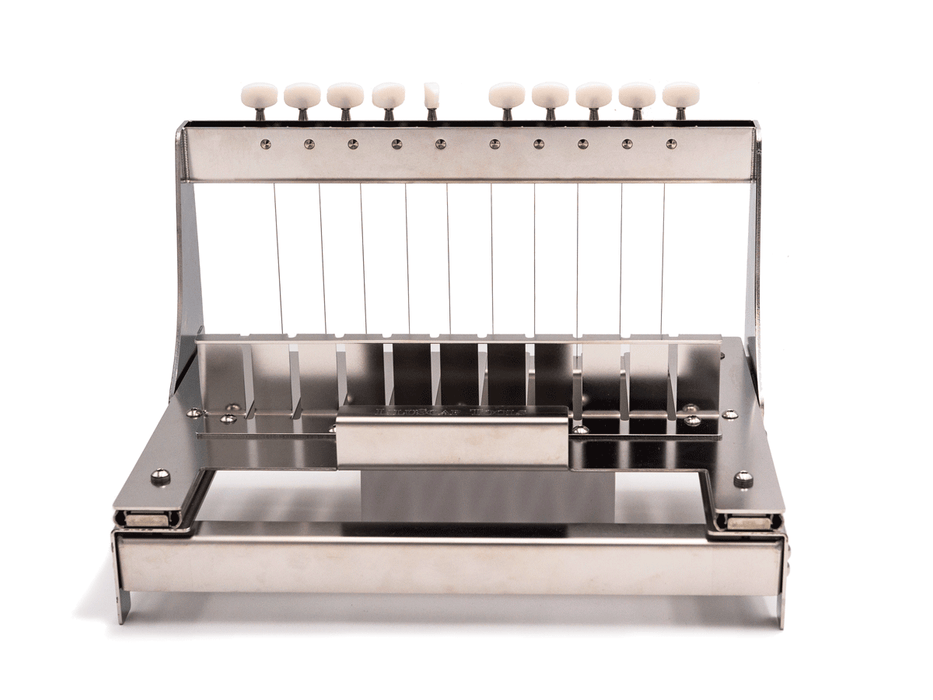

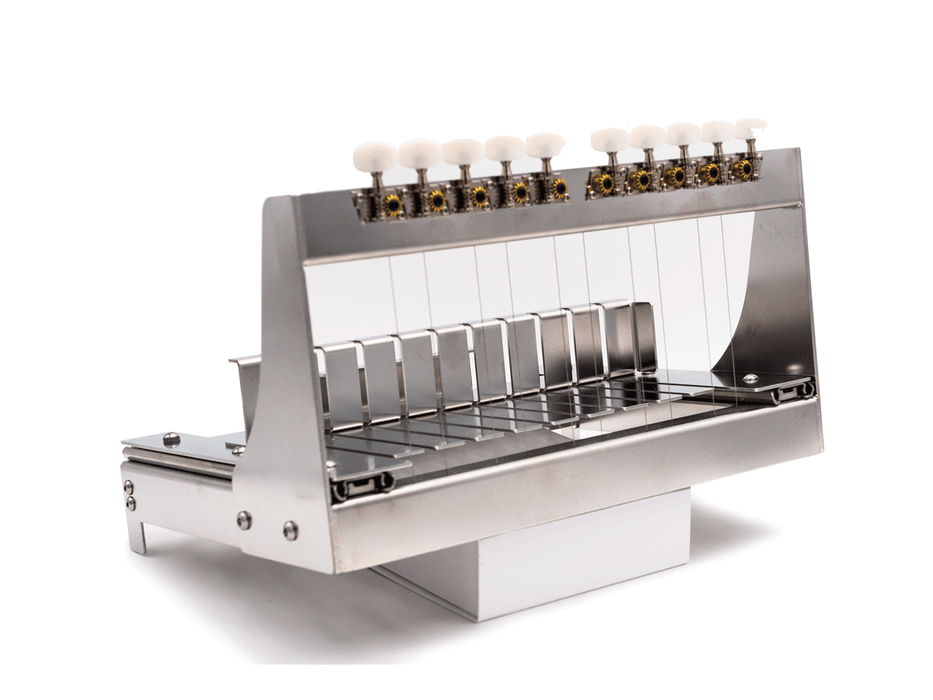

SmoothCut™ Multi-Bar Soap Cutter 2.0

- Every single part is made of medical-grade 316 stainless steel, which resists stains, chemicals, and is contamination-free.

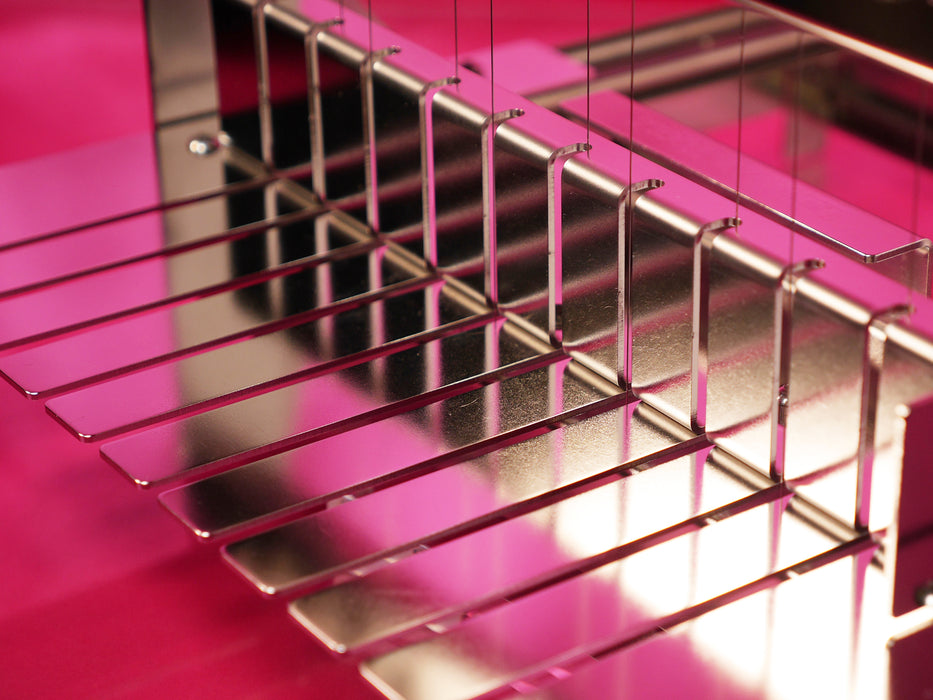

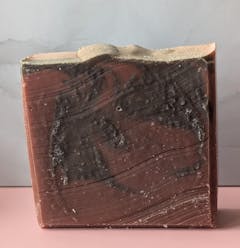

- Performs smooth cuts without leaving any curvy cutting marks.

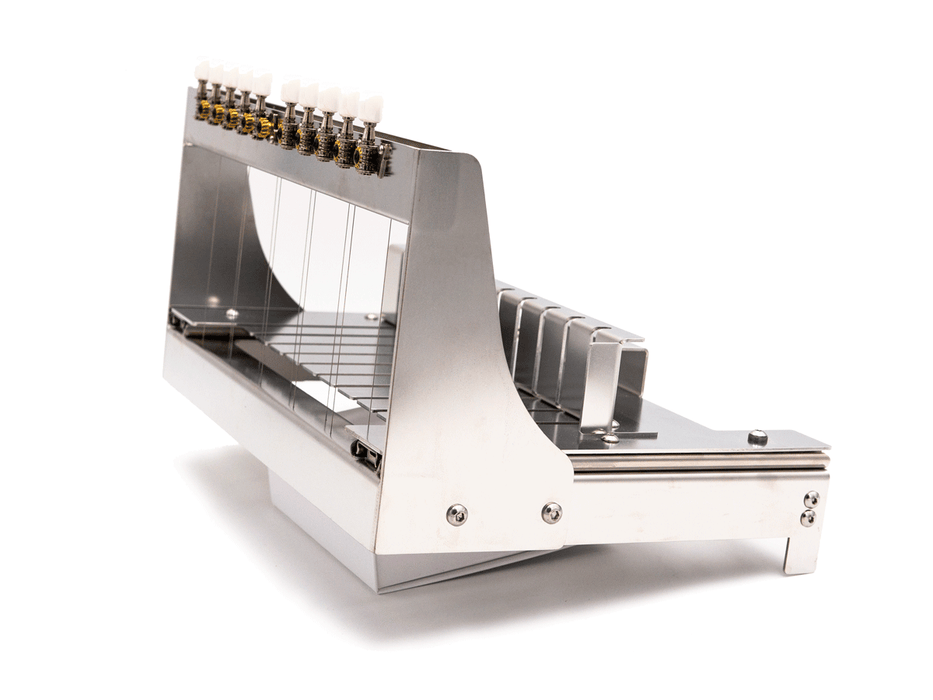

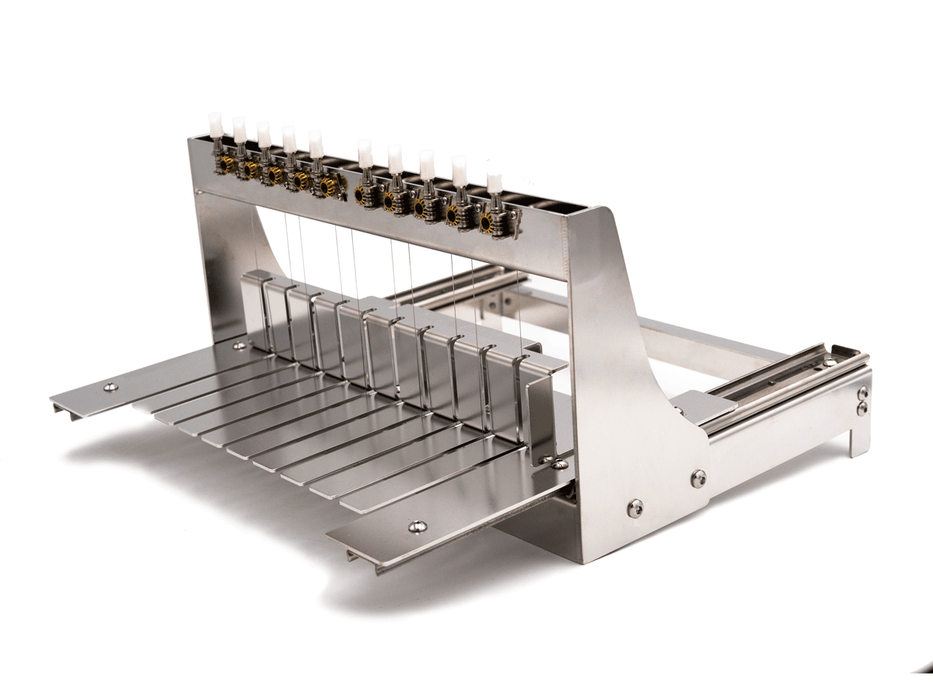

- All ten strings are easy to change.

- It is a cinch to clean in the kitchen sink or a dishwasher.

- It comes with five spare strings.

-

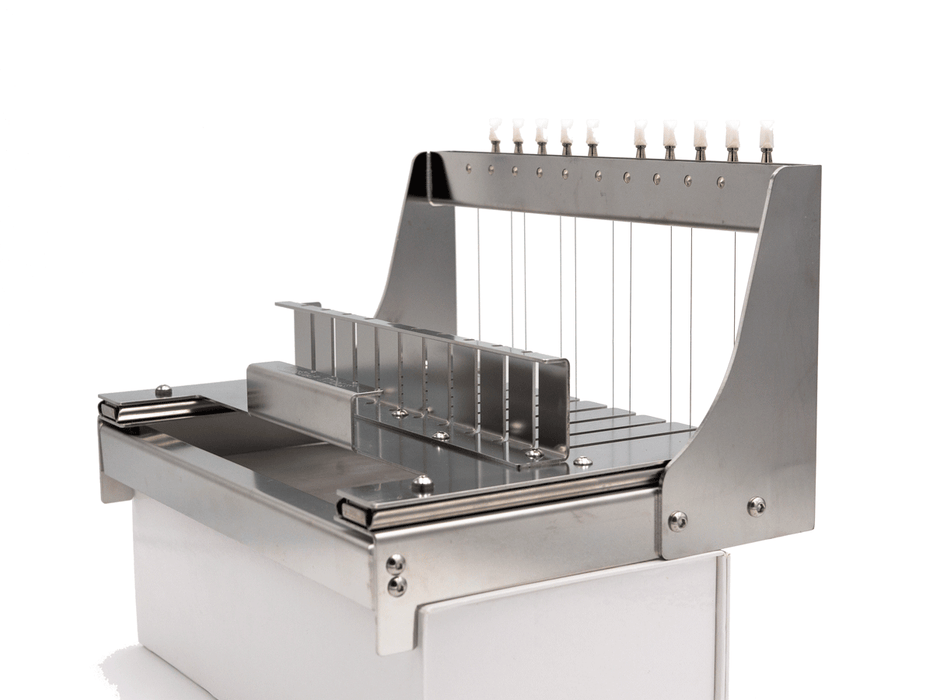

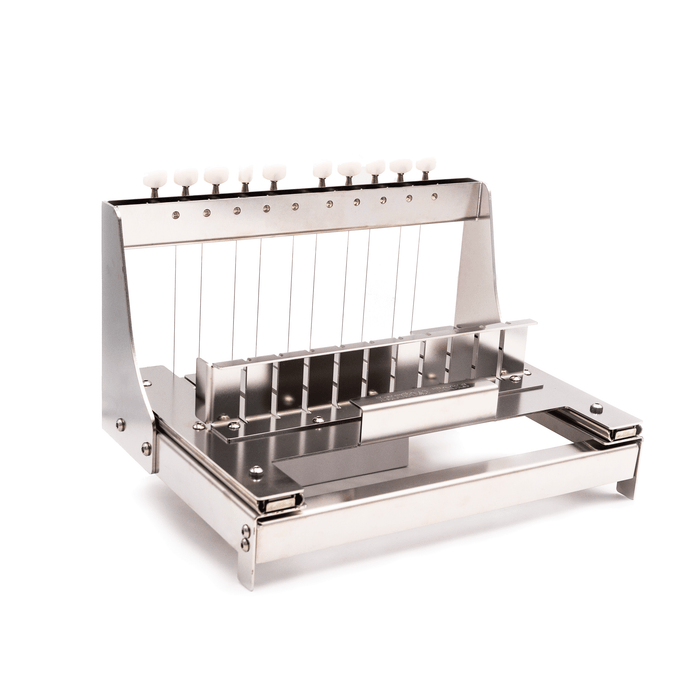

Remove the second string and use the first string as a single string cutter to cut any thickness, which is very useful for making samples.

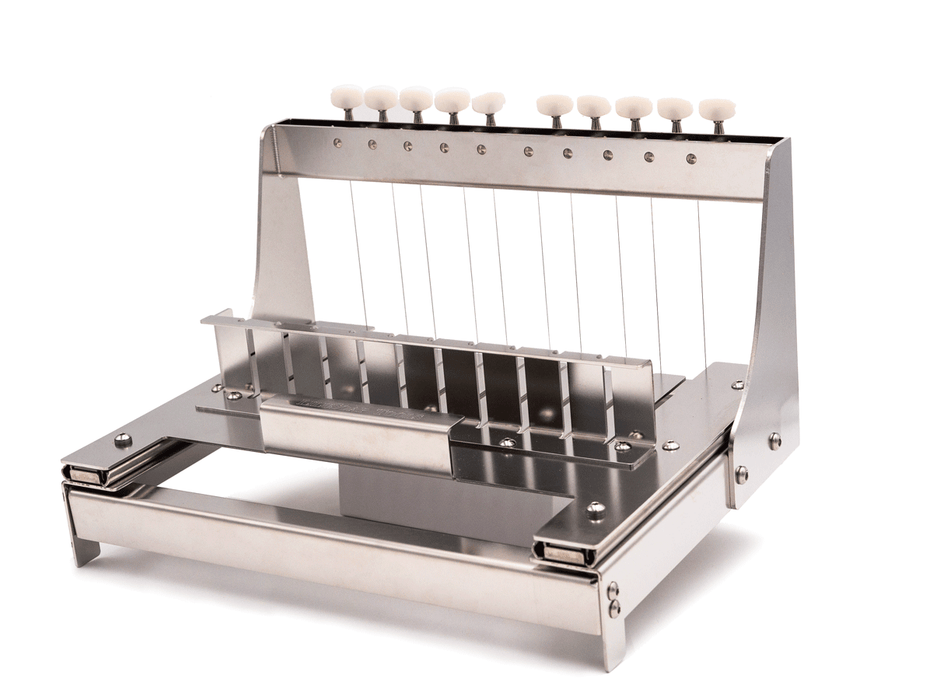

SmoothCut™ Multi-Bar Soap Cutter 2.0 has two feet that you can hook over the edge of your workbench. Simply push the handle and cut eleven bars of soap with nice and smooth surface.

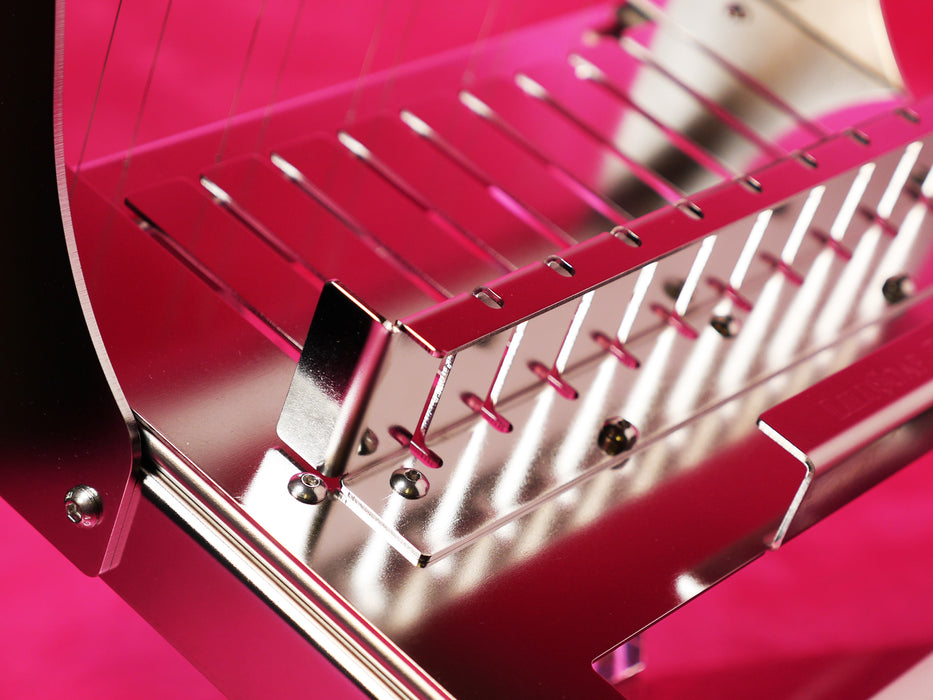

The "offset" strings placement and the innovative mechanism behind this cutter produces a clean and effortless cut through soap loaves without leaving any curvy cutting marks like other cheese-cutter type cutting devices on the market.

Every single part of the SmoothCut™ Multi-Bar Soap Cutter 2.0 is made of heavy-duty 14 gauge medical-grade 316 stainless steel, which is highly resistant to stains, chemicals, and contamination-free. Just spray water to clean it easily.

Please note that it cuts 10 bars of 26mm (they will be 1" after they are cured) and 1 sample bar of 19.5 mm when all 10 strings are installed. If you prefer to have eleven of exactly 1" (25.4mm) bars, please check the modified verson: SmoothCut Pro™ Soap Cutter 3.0.

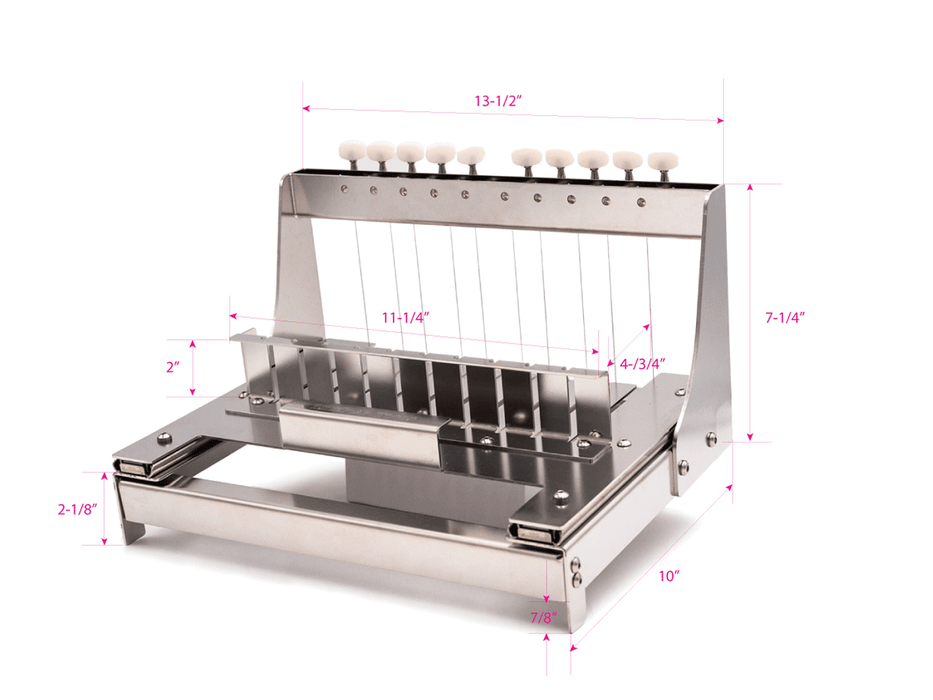

SPECS

Materials: 14 gauge 316 stainless steel for all components.

Finish: high-polished chrome finish.

Dimension: 7-1/4" H x 10" W x 13-1/8" L

(333 mm x 254 mm x 184 mm)

Cutting Capacity: 11 bar soaps each cut.

Cutting Size: 10 bars of 26mm (they will be 1" after they are cured) and 1 sample bar of 19.5 mm when all 10 strings are installed.

“Lip” height: 9/16" (1.5 cm)

Weight: 9.7 Lb (4.4 kg)

Why do you use stainless steel?

We use stainless steel because it’s durable, non-porous, and easy to clean. For soapmakers, that means less residue and faster reset between batches—especially after fragrance oils, colorants, and butters. Stainless steel also resists corrosion and wear, so your tools stay beautiful and perform consistently for years.

Why do all LiluSoap Tools® have an electropolished finish?

Electropolishing is a premium finishing process for stainless steel that creates an ultra-smooth, clean surface. This helps reduce buildup from soap residue, oils, colorants, and fragrance—so cleanup is quicker and your workflow stays consistent. It also improves 40X corrosion resistance and helps your tools keep their polished look after repeated use.